by forester | Dec 4, 2017 | News

Hello again

Well here we are at the end of another year, well, almost. I thought I’d use this blog post to tell you of one of our more unusual commissions which we undertook at the start of this year.

We were contacted by a lady who lives in a lovely flat which is virtually on the sea front. She lives in the Garden Flat and wanted a house sign. Our remit was that although it was called the Garden Flat, as it was right on the sea front, she wanted the design to be one of a ‘sea garden’. So with this in mind, we set to work.

As with all commissions, there is a certain amount of experimentation which needs to be done to decide what works best. We fired several examples of the wording for example: we tried black paint to do the words, which looked alright but it wasn’t very dynamic to look at. We then decided to make the letters out of glass and fire those onto the piece instead. We also had to decide whether to do a full fuse, which would make the sign very flat, or a tack fuse, which would give it a more 3-D effect. We tried both and without a doubt, the tack fuse worked best of all.

I made glass shells and a starfish to tack on to the sign. We also created a lovely effect of sea foam by using clear glass frit. We were very pleased with the finished result, which is shown below. Our customer was absolutely delighted with it, which is obviously the most important thing!

Commissions can be quite testing as you really want to get the best result for the customer as you can. There is obviously a certain amount of our pride at stake too! But you can also learn so much from doing a commission. Since we completed the house sign, we then used a similar theme to create a free-standing piece of art, which has gone down very well at the shows we’ve done this year.

The photo on the right shows the sign fused, and ready to go. The photo on the left is of the piece in-situ. We really love the reflection it creates on the wall as the sun shines through it.

This picture below shows how we adapted aspects of the commission into another piece of art.

We’d like to take this opportunity to thank Tina for choosing us to make her house sign. We really enjoyed doing it and in creating it, it has opened up many opportunities to make other pieces of art.

So, if you’re reading this and feel inspired to have something unique made, please contact us!

by forester | Jul 10, 2016 | News

The heart of the fusing industry seems to lie in America. All the fusing glass suppliers in this country get their glass from America, the most popular being Bullseye Glass, Spectrum and Uroboros. There is a reason for this: all glass is fusible however not all glass can be compatibly fused together. This is due to the Coefficient of Expansion (also known as COE). When glass is heated, it expands and contracts as it heats and cools. Glasses that aren’t compatible will expand and contract at different levels. This causes stress in the glass and any items fused using incompatible glasses will always crack. It may crack in the kiln, or it may crack a few hours coming out of the kiln. In some cases it can even crack many months later, but it will crack. To stop this. glass fusers have to use glass which is of the same COE. Bullseye glasses are always COE 90; System 96 glasses are COE96 – the two cannot be fused together as they are not compatible. The American factories work hard to produce glass with COEs which are always the same and in buying their products, you are guaranteed compatibility. This is why the glass artist usually only buys from the one factory – it avoids breakages due to incompatibility.

This brings me to the title of this blog. In the last few months of this year, glass industries in America have had to agree to strict environmental guidelines when they make their glass. Of course environmental issues have to be adhered to in industry and the glass companies in the US have always complied with the environmental guidelines. However, on this occasion, Bullseye Glass has had to instal new filtering systems on their furnaces at a great cost, and this is a cost which has had to be passed on to their customers. (Sadly, Spectrum have decided the cost of this new filtration system is too great and therefore after 40 years, have closed their factory which is a huge loss to the glass industry). Costs of glass is due to rise by 12% in August this year.

That in itself is a large increase which is to be swallowed by the glass artist however in the UK, it’s much, much worse. Since this country voted to leave the EU, the pound has crashed against the dollar in a new 31-year low. There is, at the moment, no sign of this rising. This means that the cost of importing glass from America to Britain has risen massively. As an indication, let me share this with you: back in January 2016, I made an order from the excellent AAE Glass in Florida. The cost of that order was $269.64, equating to £185.42. That same order today would cost £208.18. This is a rise of just over 12%. If you add this to the rise in the cost of sheet glass, the UK glass artist is looking at a price increase of over 24%, just to buy basic materials.

Of course, this could be temporary – I am not an economist and wouldn’t pretend to be however there ARE experts in this country and some of them are predicting a parity with the dollar in the coming weeks. That is not good news and if this continues, the UK glass artist is in serious trouble. As I write this, sterling is currently the worst performing currency in the markets.

I sincerely hope this is just a blip. Rich and I love our craft and to think of losing it is distressing. I wish all the other UK Glass fusers out there the very best of luck.

In the meantime, we are trying to carry on as normal. Rich and I have been in the studio and have lots of new things to add to the website in the next few weeks. I have remade some old favourites which have sold well, and created new items using new techniques.

That’s the thing with glass fusing: there is alway something new to try, a new product to test, a new technique and that’s what makes it so addictive. I am attending a week-long course in September at the fabulous Warm Glass studios in Wrington so I can learn even more.

We are exhibiting in a few places over the next few months as follows:

Forest and Wye Valley Open Studios – from now until July 24th. We are open every weekend and each Tuesday and Thursday. Please come and visit our studio in the garden at our home. There are 39 crafters participating in this year’s Open Studios: visit www.fandvos.org.uk to see the brochure.

3 Choirs Show at Gloucester Cathedral – exhibiting with the Herefordshire Guild of Craftsmen from 23rd – 30th July

h.Art – exhibiting at the Market House, Ledbury as part of h.Art, from 10th – 18th September

Malvern Autumn Show – at the Three Counties Showground with Herefordshire Guild on 24th and 25th September.

We do hope to see you at any (or all!) of these. Currently we do not know our plans for the Christmas period but I will post them as soon as I know.

Bye for now,

Becci

by forester | Nov 4, 2015 | News

Hello to you all on this gloomy, November day. This is the sort of day where the dogs stay in bed until about 4 pm and I largely wish I was with them. We have a new addition to our household: Piper. Piper is a rescue puppy from Tunisia, and she has been with us for about 10 weeks. She has a habit of coming into the studio and raiding the waste bin (not the glass waste bin before I am vilified for cruelty, but the waste paper bin). She is very, very cute, chewing the life out of everything and currently making the oil delivery man feel very unwelcome.

Anyway, I digress. Since I last wrote, we have had good news. The Herefordshire Guild of Craftsmen has accepted us as full members. We are so chuffed with this because it really is an honour. The standard of work from the other members is just astounding. Take a look at the website: herefordcraftguild.org.uk to see what I’m talking about. We will be exhibiting with them again from 4th – 20th December at the Market House at Ledbury.

November is a very busy month for us (I have taken a tea-break from the studio to write this blog). We have a lot of craft shows and additionally have had commissions to work on too. I thought you might like to know when and where we are exhibiting up until Christmas, so here is the full list:

November:

- 7th Worcester Guild Hall (10 – 4.30pm)

- 21st & 22nd Broadfield Court Vineyard Estate, Bodenham, for their Christmas Fair (10.30 – 4 pm)

- 27th & 29th Worcester Guild Hall, as part of the Worcester Victorian Christmas Market

December

- 4th – 20th Ledbury Market House, exhibiting with Herefordshire Guild of Craftsmen

- 11 & 12th Hereford Cathedral, as part of their Christmas Fair (open Friday 3.30pm – 7 pm, Saturday from 9.30 – 4 pm).

I don’t yet know the start and finish times for the Victorian Market or the Ledbury Market House, but will keep you posted.

We also have some new items coming on the website soon. We have made a new seahorse panel in the same style as the dragonfly panel and are about to start fusing and slumping glass flowers – proper glass flowers with stems. Here’s hoping the air is not too blue in the studio when we start those as it’s something completely different.

And just because I can, here is a picture of my babies:

Bye for now!

Becci

by forester | Jul 30, 2015 | News

Greetings one and all. Unfortunately, I have had a period of illness and have been unable to work on our lovely glass business. Thankfully, I am now fully recovered and raring to go….almost. Whilst on my sick bed, I have, however, been able to imagine designs and things I can create which are a little bit different.

Which brings me to the title of this blog. A friend asked me recently how I liked my glass to be perceived. I immediately thought of unique and/or unusual. On looking on the internet, however, I see that the word ‘unique’ is paradoxically ubiquitous! That leaves ‘unusual’. Here is the tricky bit though: unusual is very much a subjective opinion. What is unusual to some may not be to others. I am still pondering on this: if I want somebody to find our glass on an internet search, looking for ‘unique’ and/or ‘unusual’ fused glass, actually brings up an awful lot of sites. Clearly us glass artists all want to be seen as such! This is something I will have to ponder on for a little while longer but in the meantime, any comments or ideas would be gratefully received!

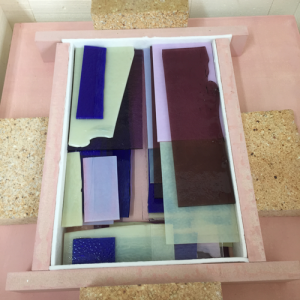

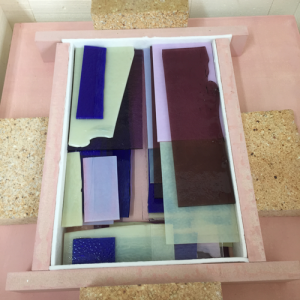

Currently in the studio, we are trying out pattern bar techniques. The fusing in the kiln is only a small part of it: there’s the initial firing, which takes about 24 hours in the kiln. The resulting slab then needs to be cut into pieces on a tile saw, assembled into a ‘pattern’ and refired. After this refiring, it needs to be cold-worked: cold-working is using machines such as lapwheels to grind into shape and polish before finally being slumped into a mould. These are the pieces I’m working on, the stage they are currently at, and the way they began life in the kiln.

Left image: the start of the whole process. Right image: how the piece currently stands, waiting to be cold-worked.

Below: left image, waiting for second firing in the kiln. Right image: how it currently stands, waiting to be cold-worked.

Our next show is for Herefordshire in Art, known as h.Art. We will be displaying upstairs in the Market House at Ledbury from 12th – 20th September, alongside members of the Herefordshire Guild of Craftsmen (we are not full members, but are Associates of the Guild). Please come along and visit, not just for our stuff but also to see the quality of the work produced by members of the Herefordshire Guild. They are all, without exception, seriously talented (check out http://www.herefordcraftguild.org.uk). Rich and I are completely in awe of them all and it’s a privilege to exhibit alongside them.

Well, that’s it for now. Back to polishing….

Becci x

by forester | Feb 9, 2015 | News

SUCH a long time between blogs. This has to change (note to self: don’t be such a lazy ass). Anyway, hello to you all – I won’t say ‘happy new year’ as that was like eons ago.

So, we are back to the studio but without the madness of Christmas. I actually quite like this down time because it gives me chance to try out new things which I don’t have time to do in the latter half of the year.

I’ve been working on some new jewellery and it is such good fun. What isn’t such good fun is trying to master the digital camera to take photos of said jewellery. Crikey, cameras these days are ridiculously complicated. On my 13th birthday, a couple of centuries ago, my parents bought me a Halina camera. It had no instructions – not because it was the equivalent of a Fisher Price toy, but because it was so simple, you just didn’t need them. You basically decided if you were indoors or outdoors and whether it was day or night and that was the limit of the decision-making process. In a nutshell, flash or no flash. Now I admit, the quality of the photos were rubbish but at least I’d only spent half a second taking the photo. Nowadays, if you can’t master the camera, the photo is still rubbish but it’s taken 45 minutes to get to that state of ‘rubbishness’. Anyway, I continue to excel at bad photos. I need to resolve this problem!

I have just attended another class at the excellent Warm Glass studio at Wrington. The quality of their teaching is just superb and I can’t wait for my next one in May. Sadly, due to the sat-nav in my car, it took me AGES to get home as I got horrendously lost. There seems to be a bit of a theme here – technology……Thank goodness the kiln is easy to operate!

We will be adding a whole new range of products in the coming year. New products are exciting to make but there’s also the slight apprehension when you open the kiln after they’ve been fired! We will obviously let you know when new ‘stuff’ arrives in our shop.

Bye for now!

Becci x

by forester | Sep 24, 2014 | News

Hi and welcome to our first blog! It’s Becci here and although I am writing this first blog, I’m hoping that Rich will take his turn too occasionally……..

It’s hard to know where to start so I figured I’d just share with you what I’ve been doing in the studio this week, which is micro-casting. This involves the use of powdered glass painstakingly added to a silicone mould with drops of water (and hopefully no air bubbles….) and then frozen. After a few hours, the glass is ‘popped’ out of the moulds and placed on a kiln shelf ready for firing.

You may wonder how on earth the heat of the kiln doesn’t reduce these frozen objects into puddles of nothingness. I still wonder that! All I know is that it works and, it’s very satisfying.

Putting the glass powder into the moulds takes hours. This is because I have to do lots of moulds at once otherwise it’s a waste putting the kiln on for just a couple of small items. Despite taking hours though, I love it. It’s an opportunity to sit in the studio, which is lovely and warm, put on the radio and just engross myself in the process.

I have spent hours perusing the internet for moulds to use. My favourite is this Halloween cat. He’s come out rather well, even down to the fur on his back standing on end. I’m very fond of him but, I have no idea what to do with him yet.

My next favourite is these black roses. I love gothic art and have yet to find a way to introduce it within my glass pieces but I think with these black roses, I can make a start. I have one or two ideas and when they come to fruition, I will let you see the final product.

I also love the cream and pale pink roses. They have a sort of ‘antique’ look about them. As with the cat, I’m not quite sure what to do with these yet – they are so beautiful though, I think they need to be the centre of the piece rather than just the decoration.

I’m also including pictures of these daisies. I like these because they are fun, bright and happy-looking.

The possibilities for micro-casting are endless. You can see other micro castings I have done on the shop page – the blue soap dish has micro-cast shells on its edge. In the meantime, I’m going to keep the radio on, the radiator blasting and will continue to indulge myself in the art of micro-casting. I’m looking for a bat mould – but I’m having trouble sourcing that!

Until next time – when hopefully this will be written by Rich…..

Best,

Becci x